MEENAKSHI TMT BARS

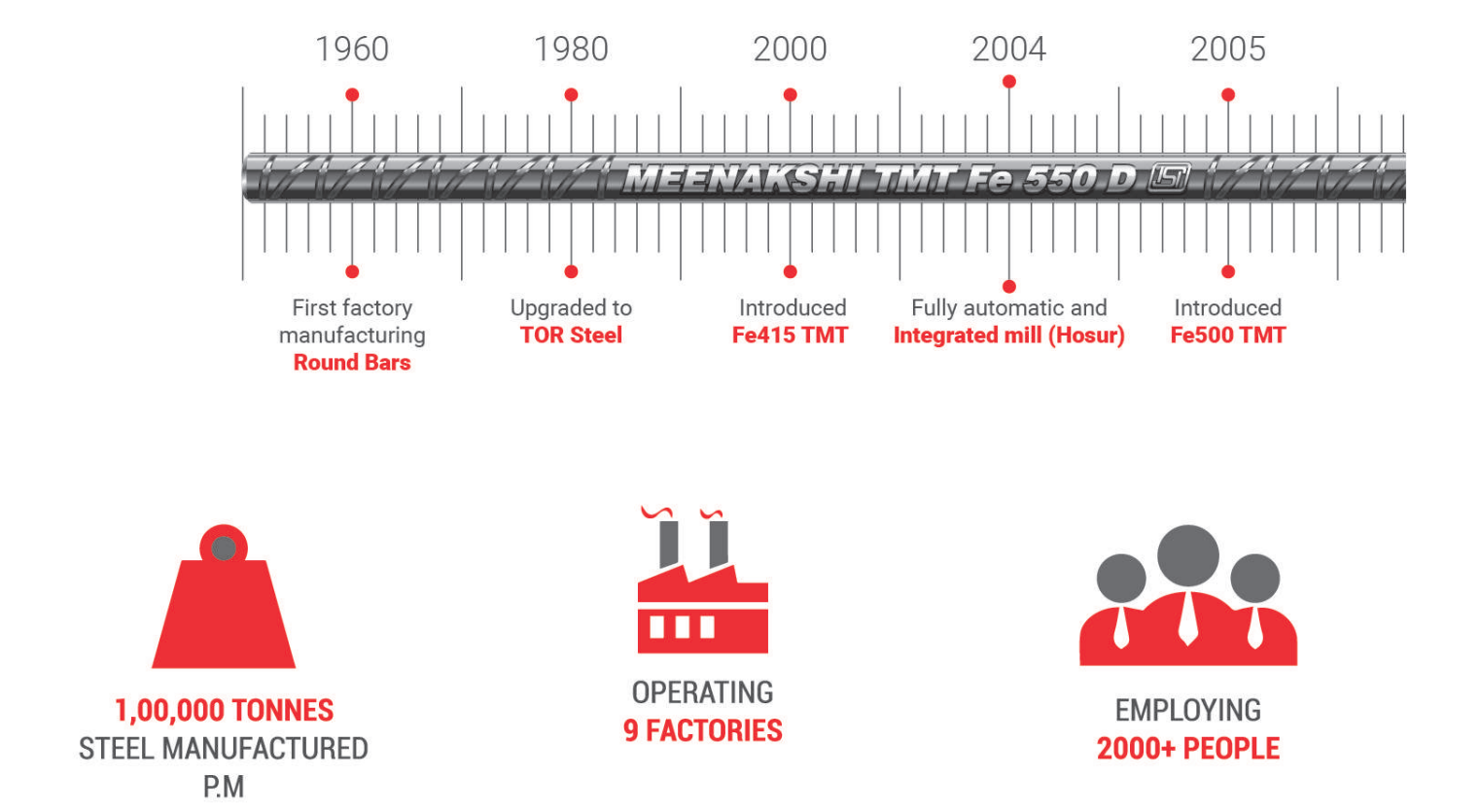

Meenakshi TMT is a reputed manufacturing company that spans decades of craftsmanship and knowledge in producing the most premium, reliable, high quality steel construction materials, especially in the form of structural steel and TMT bars.TMT bars support the very foundation of every home and building which we believe makes it one of the most essential components of a construction.

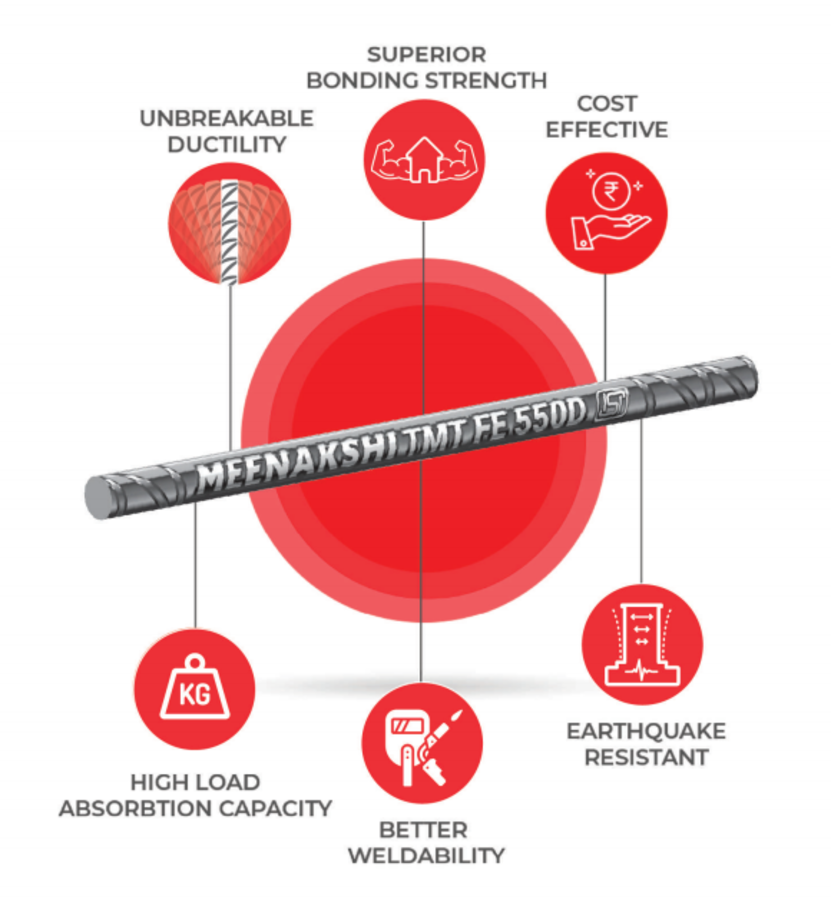

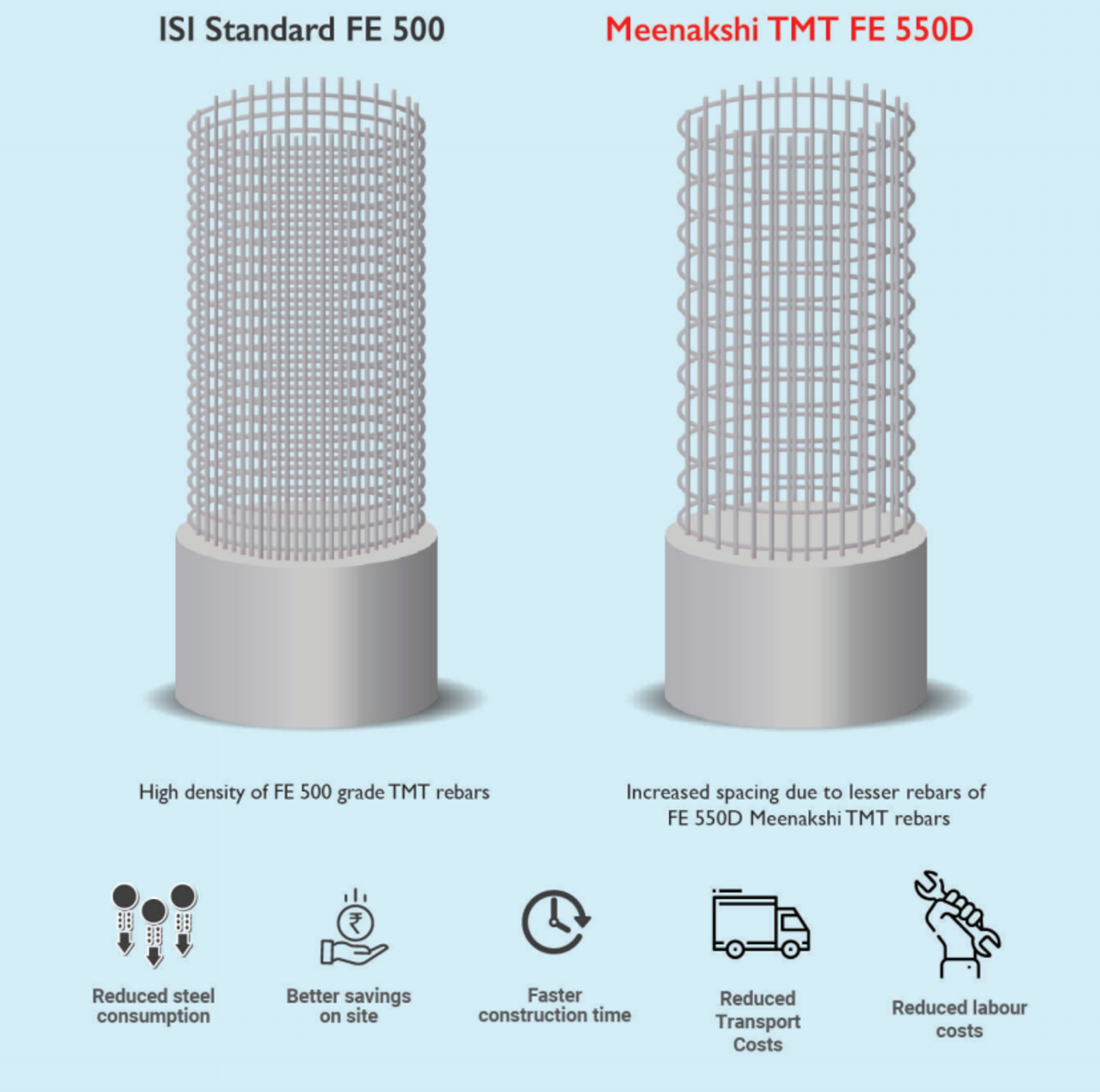

Meenakshi TMT bars are acclaimed for their affinity towards superior bonding with concrete, that ensures that the building is stronger and will last longer. They are durable, ductile, strong, reliable and seismic and corrosion resistant.

With Meenakshi TMT bars, we can assure you that your construction will result in

Strong Bonds Stronger Buildings

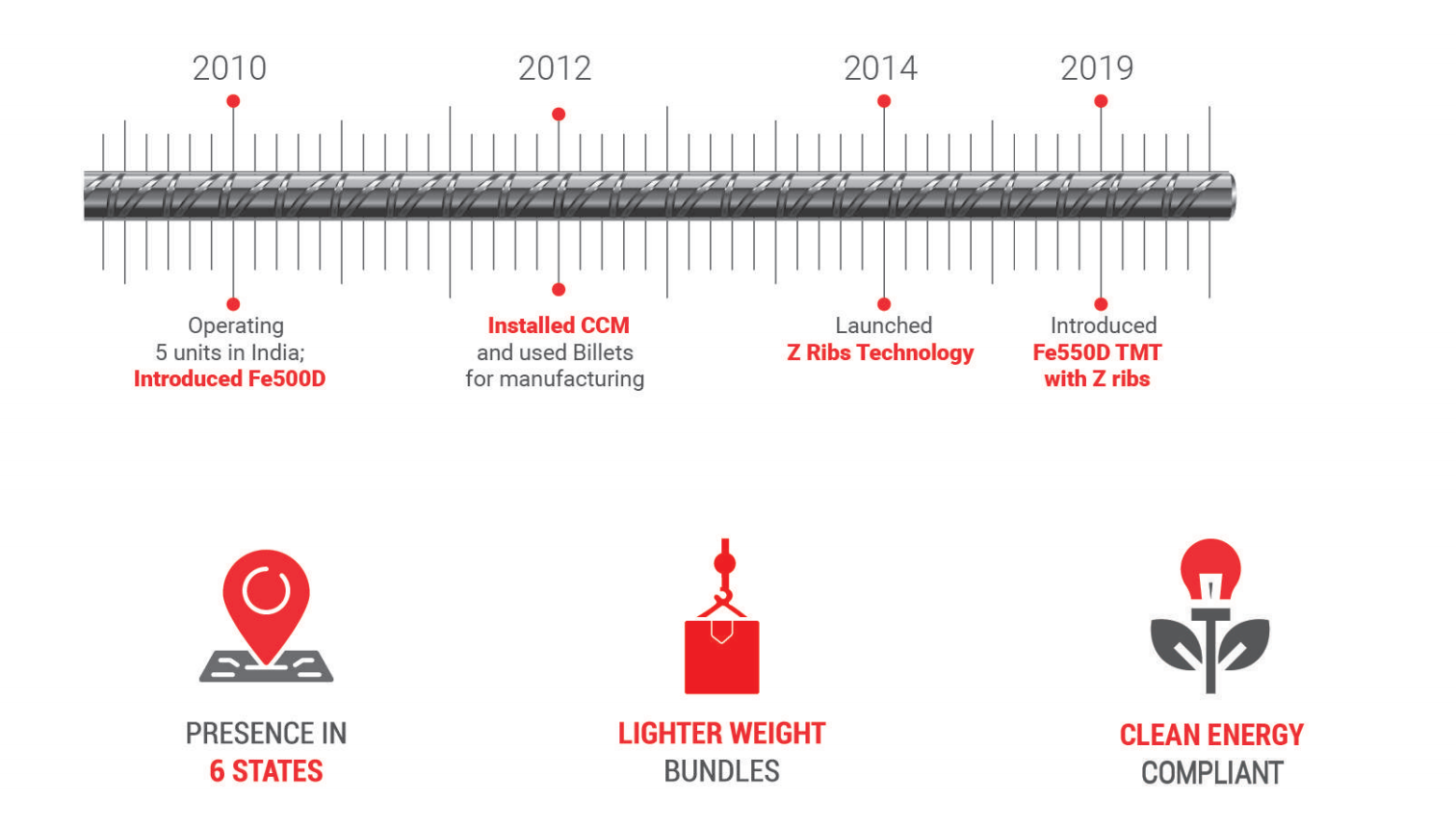

Meenakshi Steel strives to follow a zero-wastage, non-pollution system to ensure that our production process is more environment conscious. It is our responsibility to take steps to protect our environment to the best of our capabilities and Meenakshi Steel does extensive research and development to find the best, environmentally friendly technologies and methods to carry out our processes.

The Meenakshi Group now has its presence all over India covering over 6 states in different strategic locations. It has been serving the industrialists and construction companies across India with excellent quality TMT bars and Structural steel. It's factories are located in Hosur, Pondicherry, Sagar, Datia, Jhansi, Hyderabad and Pune to cater to all your requirements.

All Meenakshi TMT bars are stored in an indoor shed to prevent any external damage due to natural causes and to maintain the premium quality of our steel. All Meenakshi TMT shipments are gate and wire sealed to ensure there are no pilferages on transport. This reduces weight and transport costs. Every shipment comes with a test certificate to ensure standard quality.