KAMADHENU TMT BARS

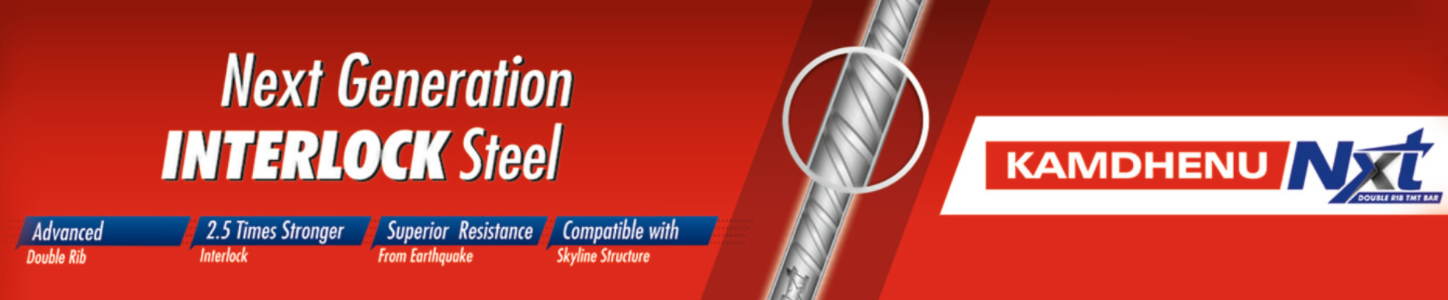

As a new dawn ignited the financial development of India, intermingled reform ideas were presented in the policy framework of the government. This year, the infrastructure development was being put greater emphasis which in return, wilhncrease the demand for steel. We, at Kamdhenu Limited carry innovation in our veins and stand high to produce products which can fulfill the diverse demands of the masses. In our country, the most challenging task for us is to create something technologically advanced within the affordability of our customers. Constructing a building is like constructing the dream of a new future and innovation is the key towards that. That is when our highly ambitious product Kamdhenu Nxt originated.

Today, there is a lot of population pressure and the cost of land is high. These demographics surely affect the growth in construction sector. Kamdhenu Limited looks forward to receive advantage from the present scenario and the envisaged future construction boom by ensuring the supply of high-end construction products at competitive prices. Mr. Sunil Agarwal. Director, Kamdhenu Limited says. "Our country is foreseeing a record allocation of Rs. 3.96 trillion to infrastructure sector. Therefore, the spotlight on reinforcement structures like ports, roads and other areas like affordable housing, physical infrastructure will provide necessary momentum to the steel sector to meet its growth targets."

The company has planned to utilize every opportunity in the new financial year so as to achieve the set targets and create new demands in the market for innovational steel products like Kamdhenu Nxt. Keeping the pace matched with developmental process with the tactful management of products is the motto of the company in the new world of unlimited possibilities.